DECA SW 100 LAB Pneumatic Arm Spot Welder With Synergic Adjustment Of The Welding Parameters 1Ph-400V-50/60Hz

Description:

The DECA SW 100 LAB is a professional pneumatic arm spot welder designed with advanced microprocessor technology to deliver precision, strength, and reliability in automotive body repair and industrial sheet metal work. Made in Italy, it is the ideal solution for workshops requiring fast and accurate spot welding on steel and galvanized sheets.

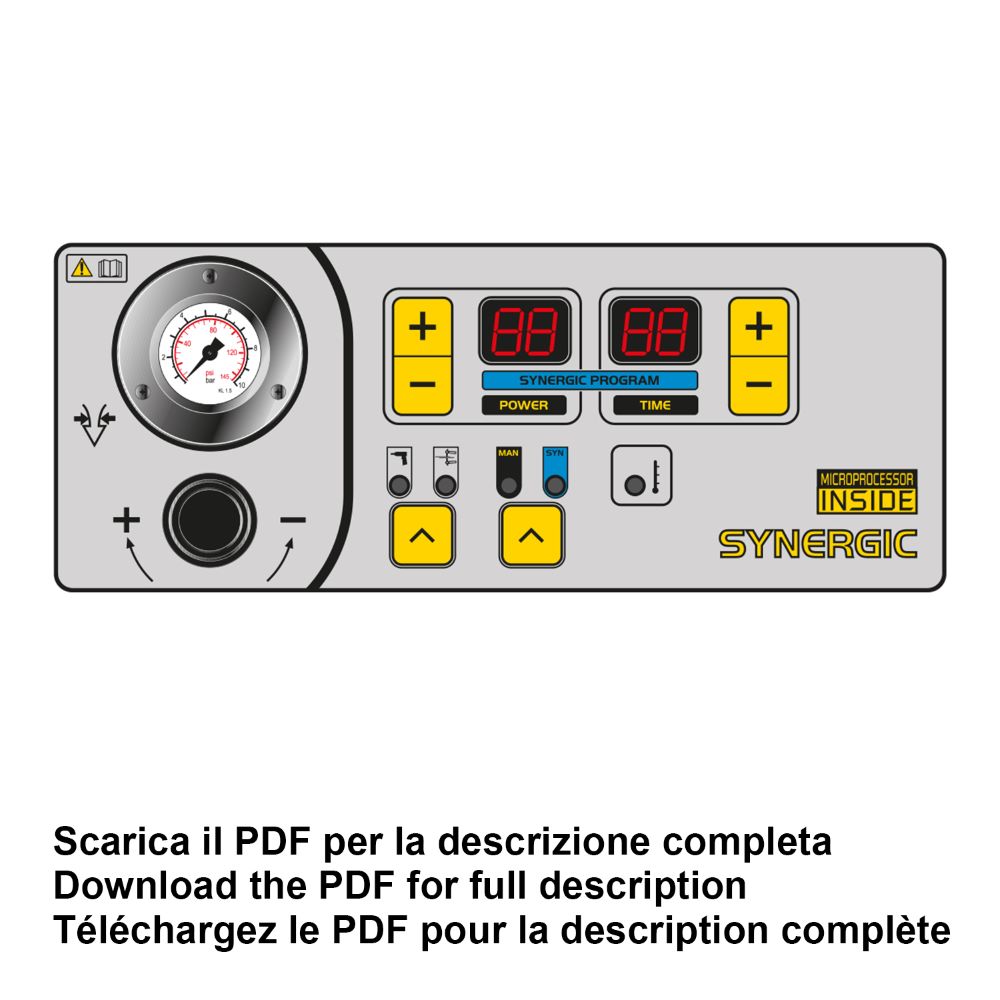

Microprocessor-controlled system for optimized welding performance.

Synergic Adjustment: Automatically sets welding parameters based on tool and workpiece thickness.

Adjustable time and spot welding current with two-digit digital control.

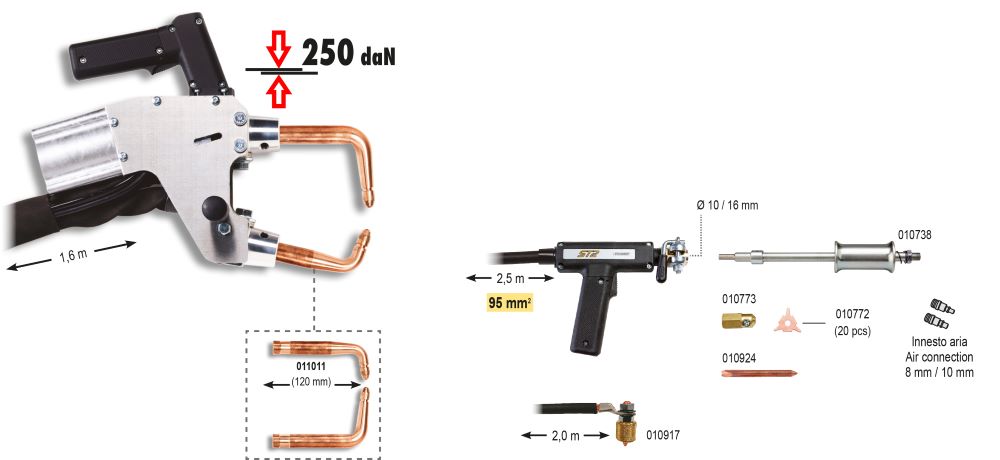

Allows simultaneous use of a spot gun and a studder gun, saving valuable time.

Pulse mode for continuous and pulsed single-spot welding, ideal for high-strength sheet metal and galvanized steel.

Sure Spot automatic compensation ensures even and consistent welding spots.

Complete with pressure reducer, trolley with arm support, and torch water cooling system for professional use.

Technical Details:

Welding Current Range (I RMS): 200 – 8000A

Open Circuit Voltage: 0.8 – 10.1V (99 steps)

Welding Capacity: 3 + 3 mm

Spots/Hour (0.8 + 0.8 mm): 600

Spots/Hour (3 + 3 mm): 75

Input Voltage (50/60 Hz): 1 Ph – 400V

Installation Power: 11.2 kW (50%) / 47.0 kW (100%)

Fuse: 32A (D)

Weldable Metals: Steel, Stainless Steel (Inox)

Features: Synergic, Pulse, Sure Spot, Welding Parameters Chart, Single Spot Welding, Pressure Reducer, Torch Water Cooling System, Copper Transformer, Thermostatic Protection

Made in Italy – DECA